Embrace innovation and spearhead the era of the Digital Factory

Strategize and cultivate culture to create the new fuel - DATA, the key to create multi-dimensional perspective to prevailing operations & efficiency using the web3 technologies & AI/ML to become a leader in the Industry.

Ensure punctual delivery every time - Monitor your shop-floor remotely

Track your ongoing execution schedules with reference to your plan from time to time to manage the delivery on time with our MES software. Dynamic rescheduling and close quality tracking helps create happy customers and outcomes.

Delight customers with your data-driven decisions

Digital quality records and end-to-end traceability enable thorough tracking of any performance issues that may arise during real-world product usage. This collaborative approach with customers enhances value for end-users.

Streamline operations to cut down on costs

Perfectly track machine KPIs like Utilization, performance on an hourly basis as data, graphs and alarms in association to the plan / product to understand and eliminate unacceptable cost incurred on each work order.

Gather data from any machine on your shop-floor

Powerful Edge Device/Application to acquire data from machines at your shop-floor irrespective of the machine make and model. Acquire process parameter and machine metrics data directly from the PLCs.

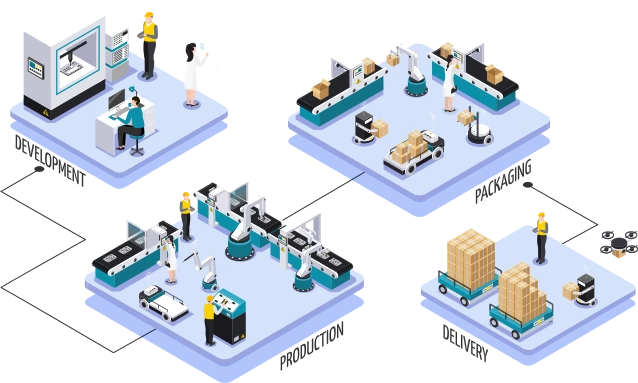

Achieve complete product lifecycle traceability

In-depth analysis of process parameter metrics across various process flows and their interrelations is essential. This is critical for predicting and comprehensively analyzing production issues and runtime challenges. Our MES solutions not only provide this analysis but also function as a comprehensive production monitoring system, enabling you to predict and address these challenges while achieving unparalleled transparency in your entire production process.

Effectively manage materials and forecast requirements

Digitize your store management of Raw material, consumables, tools and everything from inward to distribution to shop-floor, management of finished products. Understand and manage inventory and costs efficiently to optimize your operations and increase profitability.

LET’S GET STARTED